How To Replace the Oxygen Sensor

By Rob Robinette

The car's Engine Control Unit (ECU) uses the oxygen sensor

to determine how lean or rich the car is running and adjusts the air/fuel mixture

accordingly. The oxygen works in a way similar to a battery cell. Platinum layers on the

inside and outside of the probe act as electrodes. Zirconium dioxide between the layers of

platinum acts like an electrolyte. The inside layer of platinum is exposed to the air in

the engine bay, the outer layer is exposed to the exhaust. When the O2 sensor is hot it

generates positive voltage between the two layers of platinum. Negatively charged oxygen

ions in the exhaust are attracted to the platinum and reduce the voltage created by the

exhaust heat. The ECU and air/fuel gauge reads this voltage. That’s why a rich

mixture = higher voltage from the sensor (more gas = fewer negative O2 ions to drop the

voltage) . Just remember "L=L", Lean = Low voltage. You can attach a Volt Ohm

meter (black to ground, red to the O2 sensor) to monitor your engine’s air/fuel

ratio. Full throttle with 0.82 volts is best performance but slightly higher voltage

(richer) is safer. At part throttle the ECU will bounce the air/fuel ratio from rich to

lean. You only have to worry about full throttle. I suggest you have a copilot read the

voltage while you accelerate at full throttle. The 3 wire oxygen sensors are used to give

power and ground to pre-heat the sensor so it starts working quicker, it has no effect

after the sensor gets warmed up.

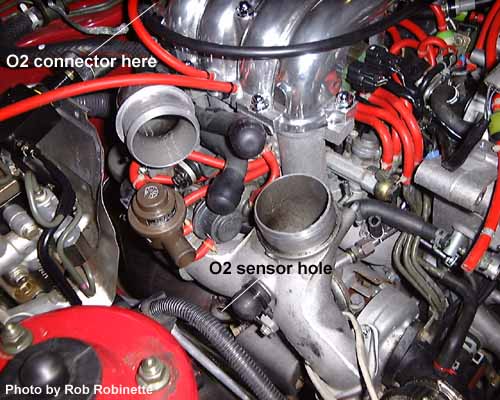

Oxygen sensor location

How To Replace the O2 Sensor

The oxygen sensor is located on the pre-catalytic converter (or

down-pipe if the pre-cat has been removed) next to the right front wheel well. You'll need

to remove the large air intake pipe that runs from the air box to the rear turbo and the

two small air lines that run from the blow off and pre-control valves to the air box to gain access to

the sensor. I recommend soaking the old sensors threads with Liquid Wrench or WD-40 over

night to make the removal easier. The O2 sensor takes a 7/8 inch wrench to remove it.

There are special sockets available (7/8" socket with a slot cut in it for the sensor

wire) to make removal of the O2 sensor easier but I don't think there is enough room

between the sensor and the right front wheel well to get the socket over the sensor. The

7/8" wrench worked fine for me.

I recommend the Bosch Universal Oxygen Sensor available at auto

parts stores for around $40. You can also install a three wire sensor if you want to

electrically pre-heat the sensor. Napa part # OS204 for 86 Ford

Escort, $50-$80, 3 wires, black wire to sensor, two white wires to power and ground

(optional). If you do use a three wire sensor connect one of the two power

wires to a ground and the other to a switched 12v power source. I recommend you stick with

a single wire O2 sensor. You'll have to splice the stock sensor wire connector (located

near the engine lift loop near the firewall) onto the replacement O2 sensor. Be sure to do

a good job with the solder gun, you don't want an intermittent connection for this

important sensor. Don't even think of just trying to wrap the wires together without at

least using crimp connectors, but I highly recommend soldering the wires together.

Put some anti-seize paste (available at auto parts stores) on

the threads of the sensor but be careful not to get any on the actual sensor (lower half).

You don't need much of the anti-seize but not using any will make replacing it next time

much more difficult. My replacement sensor already had the paste on the threads.

Screw the sensor in by hand as much as you can then tighten it

with the 7/8" wrench. Run the connector wire up and clip it into the wire holders it

was in before you removed the older one and connect the black plastic connector. Replace

the air pipes.

Rob Robinette

|